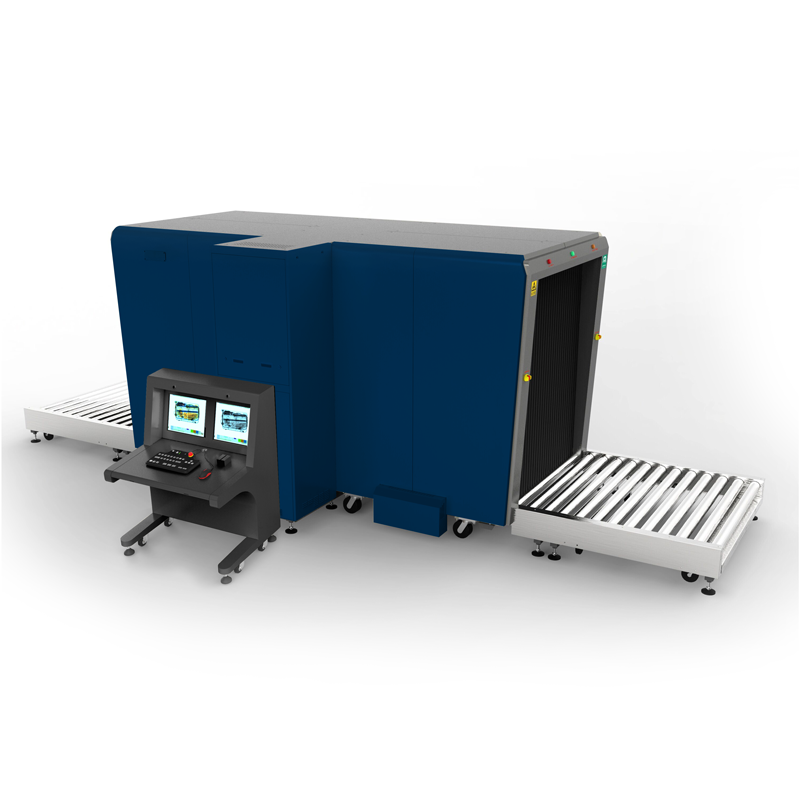

2M Technology 2MX-150180 Heavy Duty Pallet and Cargo Inspection Scanner

- 1505 x 1800(mm)/59.3″ x 70.9″ (in.)

- High density penetration capacity of 160kv

- 2x 17″ inch LCD monitors

- Uninterrupted power supply (UPS)

- Threat alert and material classification

- Baggage Counter

Note: This is a special order item. Allow 4-6 weeks for Delivery.

Product Documents

Downloads

The 2MX-150180DH is heavy duty x-ray inspection system with a tunnel opening of 59″ x 71″ inches. This scanner is designed for screening crates, cargo and pallet sized objects at all security sites, including airports and customs locations.

Key Features:

- Radiation safe

- High resolution, high penetration and good image quality

- Multilingual operation

- Automatic built in test and self-diagnostics

- Super strong load-bearing capacity

- Threat alert and material classification

- Energy saving design

- One key turn off with patent

- Drugs and explosives detection

- Sens-Tech detection board and Hamamatsu detector

| Weight | 3100 lbs |

|---|---|

| Dimensions | 280.6 × 95.4 × 92.05 in |

| PHYSICAL SPECIFICATIONS | |||

| Tunnel Size (LxW) | 1505 x 1800(mm)/59.3″ x 70.9″ (in.) | ||

| Unit Weight | 3100 kg/6834.3 lbs | ||

| Unit Size (LxWxH) | 7127 x 2422 x 2338 (mm)/280.6″ x 95.4 x 92.05″ (in.) | ||

| Gross Weight | 3100 kg/6834.3 lbs (Packet on wooden pallet) | ||

|

Packing Size |

#1: 463 x 273 x 240 (cm)/182.3″ x 107.5″ x 94.5″ (in.)

#2: 176 x 171 x 53 (cm)/69.3″ x 67.3″ x 20.9″ (in.) #3: 176 x 171 x 53 (cm)/69.3″ x 67.3″ x 20.9″ (in.) #4: 113 x 89 x 142 (cm)/182.3″ x 35″ x 55.9″ (in.) |

||

| GENERAL SPECIFICATIONS | |||

| Conveyor Speed | 0.2 m/s (0.66 ft/s) forward and reverse | ||

| Conveyor Height | 350 mm | ||

| Conveyor Capacity | 2000 kg/4409.2 lbs | ||

| Frame Materials | 304 stainless steel, 2-5mm cold rolled plate and square steel, double-layer staggered lead impregnated safety curtain | ||

| X-ray Dose/Inspection | ≤4.5μSv | ||

| X-ray Leakage | ≤1μSv/h at any point 5 cm outside the external surface. FDA standard is ≤5μSv/h | ||

| Steel Penetration | 34 mm guaranteed | ||

| Wire Resolution | AWG38 guaranteed | ||

| Penetration Resolution | AWG32 guaranteed | ||

| Spatial Resolution | 1.3mm Horizontal, 1.3mm Vertical | ||

| Power Consumption | Max. 2KW | ||

| Noise | <60 dB | ||

| Film Safety | Guarantee ASA/ISO1600 Film | ||

| X-RAY GENERATOR (SINGLE) | |||

| Anode Voltage | 160 KV | ||

| Beam direction | Horizontal | ||

| Cooling / Duty Cycle | Sealed oil cooling /100% | ||

| COMPUTER AND OTHER | |||

| Monitor | 2x 17″ inch LCD monitors, 1280 x 1024 | ||

| Console | One console desk | ||

| CPU | Intel (R) i3 (R) 3.3GHz | ||

| RAM | 4GB | ||

| Hard Disk | 2TB | ||

| Keyboard | Special Design | ||

| Platform | Windows® 10 | ||

| Backup | Uninterrupted power supply (UPS) | ||

| Electric Roller | Three-phase | ||

| IMAGING SYSTEM | |||

| Detector | 3712 channels in an L-Shaped Array | ||

|

Image Processing

|

Color/black and white imaging, local enhancement, high pene-

tration, low penetration, super enhancement, organic stripping, inorganic stripping, reverse color, brightening, darkening, gray level scan/variable density, continuously zoom maximum 64x, pseudo color imaging, organics enhancement, suspicious item alarm and notation, edge enhancement imaging, etc. |

||

| Explosives & Narcotics Detection | Suspicious organics highlight (atomic number Zeff=7,8,9) | ||

| Suspicious Alarm | Alarm and box line the suspicious objects including hard to pene- trate material, explosives and drugs |

| Threat Image Projection (TIP) | Insertion of fictional but realistic images of threatening items into baggage during screening operation for training purposes to assess image identification capabilities |

| Image Pullback | 30 images |

| Image Archive | Up to 100,000 images stored automatically, can be transferred to a

USB disk, and converted to JPG, BMP and other general formats |

|

Miscellaneous Functions |

Time/date display, counters, user management, system on/x-ray on timers, power on self test, built-in diagnostic facilities, bi-direction- al scanning, forced scanning, image search and export, system setting, system log, system standby and simulation training, etc. |

|

Options |

Intelligent roller, remote work station, network integration, video monitoring, face recognition and baggage integration, recheck station, additional roller table, etc. |

| OPERATING ENVIRONMENT | |

| Operation Temperature | 5°C to 40°C (41°F to 104°F)/0%-90%(non-condensing) |

| Storage Temperature | -20°C to 140°C (-4°F to 104°F) /10%-90%(non-condensing) |

| Operation Power | 220V(10%~ -15%) 50±3Hz (Options: 100-130V, 200-250V, 60Hz) |

| UPS (Optional) | Options: 15mins, 30mins, 60mins etc. |