2MX-240DT-160KVL Drive Through Vehicle Inspection System

- Continuous scanning

- Avoids scanning the driver for safety

- All information is stored in the system

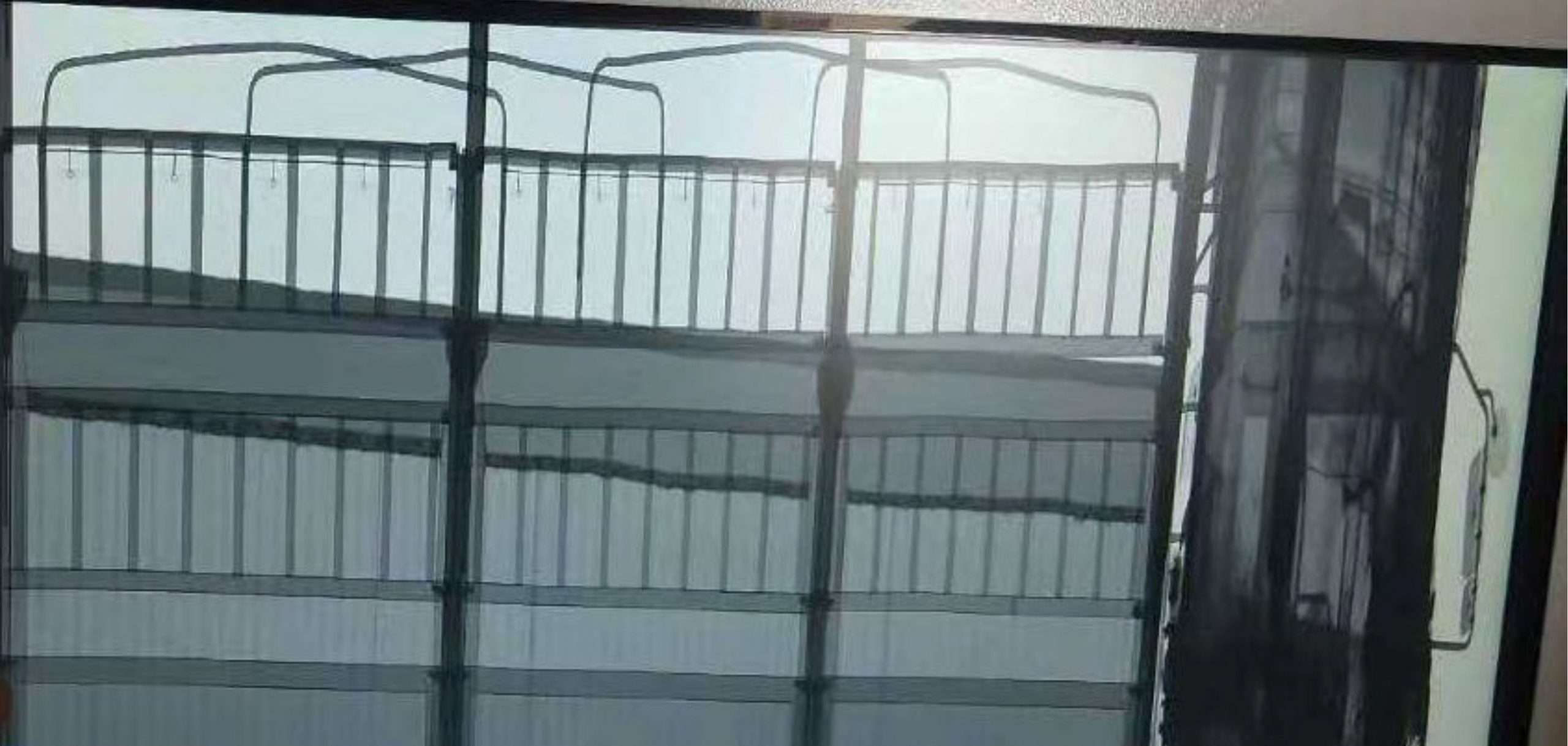

- The x-ray images clearly show a detailed image of the compartment

- Identifies the information of the scanned vehicle, including the license plate number, color, etc

Product Documents

Downloads

Overview:

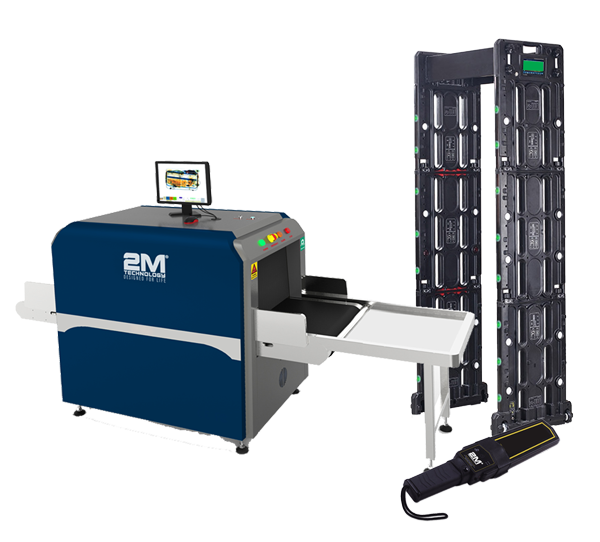

The 2M Technology x-ray vehicle security screening system, helps to quickly detect dangerous goods and contraband hidden in a vehicle. Based on the intelligent model, the automatic detection system conducts a complete inspection process, so the vehicle can be inspected while moving, and the loading condition of the vehicle can be clearly discriminated. It integrates x-ray scanning technology with License Plate Recognition (LPR) and video monitoring to provide comprehensive information for inspection accuracy.

This product is mainly used in road checkpoints for loading and positioning. Initially for tractor trailer inspections, it can be customized for different requirement. The system can be customized to fit customer requirements and conditions of the installation site.

Features:

- When the vehicle is passing through the channel, its cargo is continuously scanned. Driver cabin is not.

- After scanning, the vehicle’s information, a side video of the vehicle and its x-ray fluoroscopic information image are generated at the same The loading rate of the vehicle is automatically calculated, and the cargo conditions in the car compartment can be analyzed and differentiated in detail.

- The x-ray images clearly show a detailed image of the compartment, and synchronously prompts the inspector to

- Automatically identifies the information of the scanned vehicle, including the license plate number, color, etc

- The inspection data and inspection results are automatically stored according to the inspector’s login information for later use, The vehicle side video and x-ray image are also

- Includes standard Ethernet interface for remote monitoring, debugging and data

Operation:

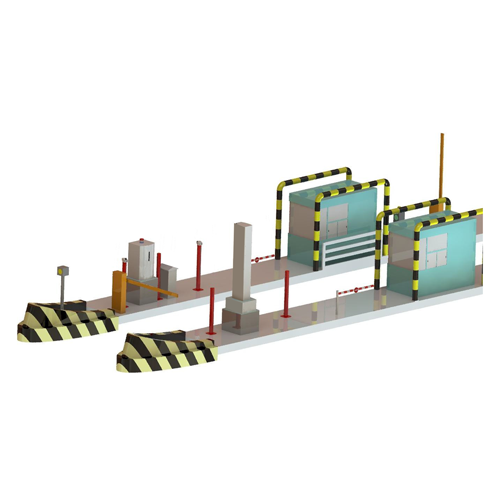

- When the green indicator light is on, the vehicle is allowed to enter the detection area.

- The front ground coil senses the vehicle, the road barrier automatically lifts up and the vehicle can enter the detection area.

- As the vehicle passes the back ground coil, the road barrier automatically falls, preventing other vehicles from entering the detection area.

- When the vehicle blocks the start sensor, the License Plate Recognition camera takes a picture of the front of the vehicle and automatically records the license plate number and the speed of the vehicle. At the same time, the red indicator light of the x-ray machine lights up to remind the staff that the high voltage has been turned on.

- When the vehicle blocks the mid-sensor, the side camera starts taking the side video and the x-ray is powered on (note: the red indicator light is on,

but no x-ray is generated). - When the vehicle blocks the end sensor, the front of the vehicle has passed the x-ray source by 2m~3m to ensure that the cab is not exposed to x-rays, the yellow indicator light is on (x-ray is on) and the x-ray scans the vehicle compartment as it’s moving.

- When the rear of the vehicle leaves the mid-sensor, the x-ray ends the scan. The yellow warning light turns off and the side camera stops recording.

- When the rear of the vehicle leaves the end sensor, the x-ray power supply (high voltage) and the red warning light are turned off.

- After the vehicle exits the scanning area, the user can press the “Confirm” button and the system is ready for the next vehicle.

Imaging:

- The imaging system has the functions of prompting alarm, history data search, printing, etc.

- The main interface displays the current status of the system (automatic, manual), vehicle position, vehicle speed and other information.

- The search interface contains information such as License Plate number, time, result, judgment result, vehicle model, entrance, exit, charging result, tax exemption amount, replenishment amount, and inspector.

- You can choose a fixed time or a fixed inspector to generate the form.

- The image storage format adopts HIS format and can be converted to common and standard image storage formats.

- The stored information includes real-time image of the vehicle from side, x-ray image, the image of the front of the car, the license plate number, the judgment result, the amount of the charge, etc.

|

|

| GENERAL SPECIFICATION | |

| Effective Length | 2400mm |

| Pixel Value | <2.5mm |

| Scanning Vehicle Time | <5s (15 km/h driving speed) |

| Maximum Vehicle Size | 3.5m(W) * 4.5m(H), unlimited length (depending on the length of the lane safety island) |

| Detection Speed | 3~15km/h |

| Communication | RS232, remote software control trigger |

| X-RAY GENERATOR | |

| Focus Size | Nominal value is not more than 0.8mm (according to IEC60336-2005 standard) |

| X-Ray Fan Radiation Angle | 83° x 5.0° |

| Convergence Window Radiation Angle | no more than 65° × 1.78° |

| X-Ray Generator | 160KV, sealed oil cooling |

| Tube Current | 0.3~1.2mA |

| Tube Life | >6000 hours |

| Ray Direction | Sideward |

| X-RAY DETECTOR | |

| Detector Type | Line array detector |

| Height | >2.4 meters |

| Resolution | <2.5mm |

| Voltage | 12V |

| VEHICLE SIDE CAMERA | |

| Fisheye Lens | Focal length and aperture adjustable |

| Resolution | 2048 x 1 |

| Maximum Line Frequency | 3.4kHz (To avoid low-speed trailing, line frequency will be reduced). |

| Pixel Size | 7.04 µm |

| Output Format | GigeE |

| Size | 62 x 48 x 48 mm |

| OPERATING ENVIRONMENT | |

| Power Supply Voltage | 230VAC +/- 10%, 50/60Hz |

| Power Supply Current | <2A |

| Working Temperature | -40°C ~ 70°C |

| Working Humidity | ≤ 95% (no condensation) |

| COMPLIANCE | |

| GBZ 143-2015 | Radiation Protection Requirements for Cargo/Vehi- cle Radiation Inspection System |

| GBZ 117-2006 | Industrial x-ray inspection radiological protection standards |

| GB 18871-2002 | Basic standards for ionizing radiation protection and radiation source safety |

|

IEC 60336-2005 |

Medical electrical equipment – X-ray tube assem- blies for medical diagnostics -Characteristics of focus |

| GB 2423-89 | Basic environmental test procedures for electric and electronic products |

| IEC 61000-4 | electromagnetic compatibility |

| GB/T 17626-1998 | electromagnetic compatibility |