Explosion-proof lights are essential for illuminating hazardous areas and keeping workers safe. But choosing the right fixture isn’t just about meeting safety certifications; it’s also about how well the light performs in tough conditions. If you’ve ever looked at lighting specs and felt confused by terms like lumens, CRI, CCT, or beam angle, you’re not alone. In this guide, we’ll explain what the most common explosion proof light specifications mean so you can choose the right lighting solution with confidence.

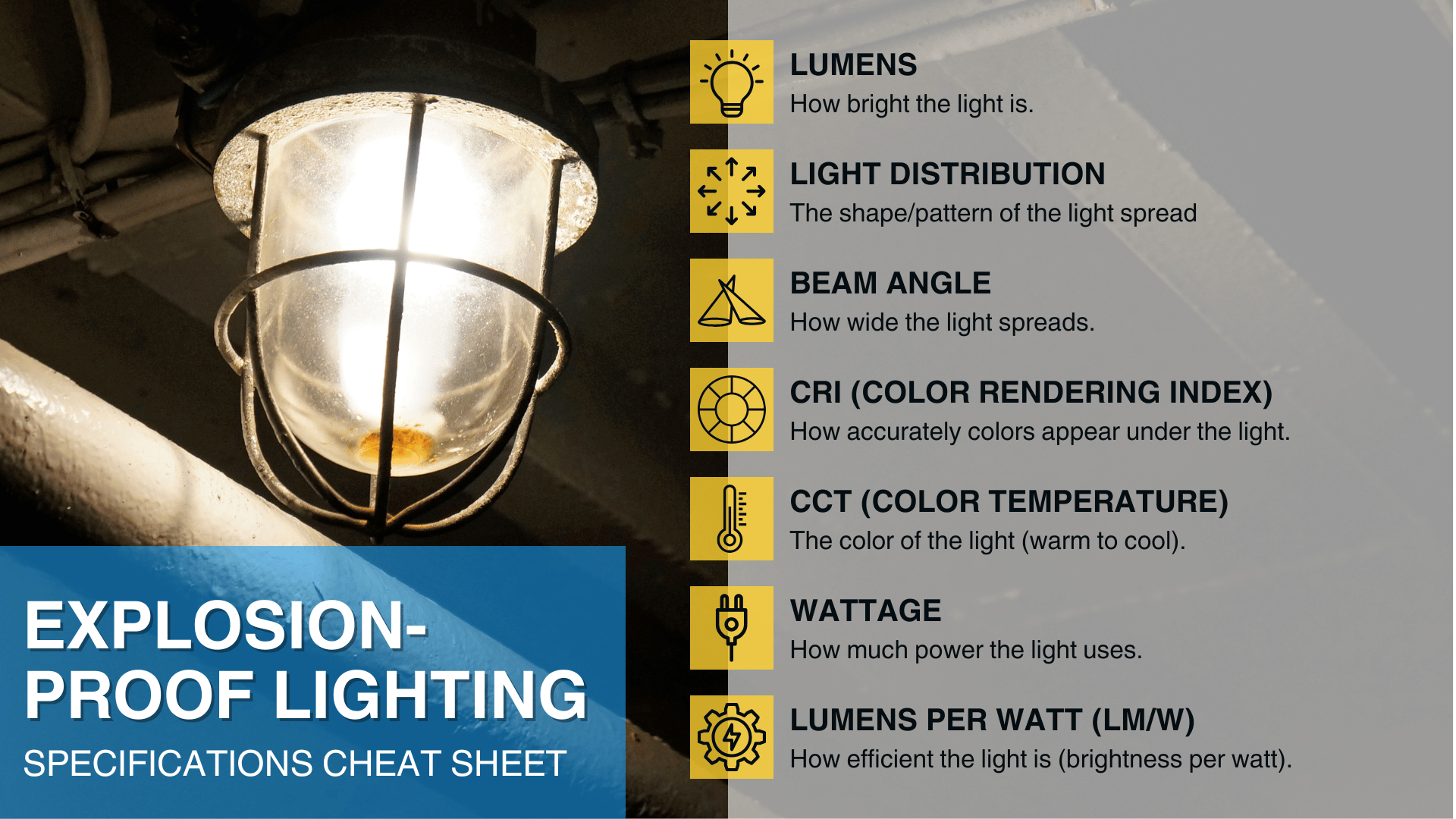

Common Explosion Proof Light Specifications

Lumens: How Bright Is the Light?

Lumens measure how much visible light a fixture emits. Simply put, it’s how bright the light is. The higher the lumen rating, the brighter the light. However, more brightness isn’t always better; excessive light can cause glare or lead to eye strain. When reviewing explosion proof light specifications, it’s important to match the lumen output to the size and function of your space. For example, a small workbench area might only need around 1,000 lumens, while a large outdoor facility could require an explosion-proof fixture with 30,000 lumens or more.

Light Distribution: How Is the Light Spread?

Equally important in explosion proof light specifications is light distribution, which determines how the light spreads across an area. Light can be distributed in different ways, depending on how they’re mounted and the type of fixture used.

-

Flood distribution spreads light over a wide area, making it ideal for large, open spaces like refineries or chemical plants.

- Spot or narrow beam focuses light in a single direction. This works well for high ceilings or for lighting specific areas, such as tanks, machines, or equipment stations.

-

Type I, II, III, IV, and V distributions refer to standardized outdoor lighting patterns often used in hazardous area lighting or street-level fixtures.

Picking the appropriate light distribution ensures even lighting, reduces shadows, and avoids wasting energy on areas that don’t need illumination.

Beam Angle: Is the Light Coverage Focused or Wide?

Beam angle refers to how wide the light spreads, measured in degrees. A narrow beam angle (30°–60°) concentrates light in a small area, making it useful for spotlighting specific equipment or task lighting. A wide beam angle (90°–120° or more) spreads light across a broader area, which is better for general lighting in places like walkways, tunnels, or storage rooms. As with light distribution, checking the beam angle in your explosion proof light specifications helps ensure the light goes exactly where it’s needed.

CRI (Color Rendering Index): How True Do Colors Look Under the Light?

CRI is a scale from 0 to 100 that measures how accurately a light shows colors compared to natural daylight. A CRI of 80 or higher is considered good for most industrial settings. In hazardous areas, high CRI lighting improves visibility, making it easier for workers to read labels, spot hazards, and perform detailed tasks. If precision matters in your facility, such as in a lab, inspection zone, or quality control station, always check CRI values in your explosion proof light specifications. This detail can make a big difference in safety and accuracy.

CCT (Correlated Color Temperature): What Color Is the Light?

CCT describes what color the light appears, measured in Kelvins (K). Explosion proof light specifications typically list CCT values within these ranges:

-

3000K (Warm White): Slightly yellow, similar to residential lighting. This is rarely used in industrial settings.

-

4000K (Neutral White): A clean, balanced white that works well for general work areas.

-

5000K (Cool White): A bright and crisp white that’s perfect for high-visibility environments and outdoor use.

-

6000K+ (Daylight): Bluish-white light often used in highly detailed work or outdoor settings.

Most industrial or hazardous areas go with 5000K, as it helps with visibility while still being comfortable on the eyes.

Wattage and Efficiency: How Much Energy Does the Light Use?

You should also consider how efficient an explosion-proof light is. Inefficient lights use more energy, which leads to higher costs. When reviewing explosion proof light specifications, pay close attention to lumens per watt (lm/W). Although wattage tells you how much power a light consumes, it doesn’t show how much light it produces. Lumens per watt is a better way to measure efficiency because it tells you how much light you get for each watt of energy. The higher the lm/W, the more light you get while using less electricity. A good explosion-proof LED fixture should provide at least 120 lm/W.

IP and IK Ratings: Is the Light Protected from Dust, Water, or Impact?

There are two more important ratings to look for when checking explosion proof light specifications:

-

IP (Ingress Protection) rating tells you how well the fixture is sealed against dust and water. For explosion-proof lights, an IP66 rating or higher is best.

-

IK rating measures how much impact the light can withstand. A rating of IK10 means the light can handle strong physical blows, which may happen in tough work environments.

These ratings help make sure your explosion-proof light remains reliable and lasts longer, even in the roughest conditions.

Need Help Choosing the Right Explosion-Proof Light?

Explosion-proof lights don’t just have to be safe; they have to perform well too. By understanding key explosion proof light specifications like lumens, CRI, CCT, and beam angle, you can select the right fixture for your space and ensure the safety and comfort of your team.

At 2M Technology, we make it easy to find the right lighting solution for your hazardous area. All of our explosion-proof lights are fully certified, energy-efficient, and built to perform in the toughest environments. Not sure what you need? We can help you select an explosion-proof light that’s bright, efficient, and well-suited for your space. Contact our team at sales@2mtechnology.net or call +1 (214) 988-4302 today.