The chemical manufacturing industry includes some of the most hazardous workplaces in the world. Facilities that produce paint, coatings, resins, solvents, pharmaceuticals, or industrial chemicals often contain flammable vapors, combustible dust, and volatile gases. Standard security cameras are not designed for these conditions and can create serious safety risks.

Explosion proof cameras for chemical manufacturing facilities are specifically made to operate safely in classified hazardous areas while delivering clear, reliable video surveillance. These specialized cameras allow chemical manufacturers to monitor production processes, improve worker safety, and meet regulatory regulations without introducing potential ignition sources.

Why Explosion Proof Cameras for Chemical Manufacturing Are Necessary

Many chemical processes involve hazardous materials that can ignite when exposed to heat or sparks, both of which can be emitted by standard electrical equipment. Without proper containment, internal sparks or heat could come into contact with flammable gases, vapors, or combustible dust. Regular cameras are not designed to contain these ignition sources, making them unsafe for use in classified hazardous areas.

Explosion proof cameras for chemical manufacturing are built with sealed, reinforced housings and certified components that contain any internal sparks or heat, preventing them from affecting the surrounding environment.

Key Benefits of Explosion Proof Cameras for Chemical Manufacturing

- Safer monitoring in hazardous zones

- Continuous surveillance in flammable environments

- Improved accident prevention and faster incident response

- Compliance with ATEX, IECEx, and NEC/UL standards

- Reduced downtime and operational risks

By installing explosion proof cameras for chemical manufacturing plants, companies can maintain operational visibility while protecting workers, equipment, and facilities.

Chemical Manufacturing Industries That Use Explosion Proof Cameras

Explosion-proof cameras are essential across many chemical manufacturing sectors. While paint manufacturing is a major example, other industries also rely on these cameras, each with unique hazards and monitoring needs.

Paint and Coatings Manufacturing

Paint production involves solvents, pigments, and flammable liquids. Cameras help monitor mixing stations, storage tanks, and filling lines while reducing the need for personnel to enter high-risk zones.

Pharmaceutical and Chemical Processing

Facilities producing active pharmaceutical ingredients (APIs) and specialty chemicals may use volatile solvents or powders. Explosion proof cameras allow operators to safely monitor reactions, packaging, and storage.

Petrochemical and Refining Operations

Petrochemical plants handle highly flammable hydrocarbons. Certified cameras help monitor pipelines, storage tanks, and processing equipment in hazardous classified areas.

Resin and Adhesive Manufacturing

Resin and adhesive production involves chemical reactions and combustible materials. Cameras provide visibility into production areas while minimizing worker exposure.

Industrial Solvent and Cleaning Chemical Production

Solvent manufacturing presents serious explosion risks due to vapor accumulation. Explosion-proof cameras improve safety monitoring and ensure regulatory compliance.

Fertilizer and Agricultural Chemical Facilities

Certain fertilizers and agricultural chemicals contain combustible dust or reactive compounds. Cameras help detect hazards early and support operational oversight.

Specialty Chemical Manufacturing

Producers of dyes, additives, polymers, and laboratory chemicals often require precise monitoring in confined hazardous environments.

Key Features of Explosion Proof Cameras for Chemical Manufacturing Plants

Not all hazardous-area cameras are the same. When selecting explosion proof cameras for chemical manufacturing, companies should focus on features that improve both safety and operational efficiency while providing reliable monitoring in high-risk environments.

Certified Hazardous Area Protection

Explosion proof cameras are built with sealed housings and components that prevent sparks, heat, or electrical faults from igniting flammable materials. Key features include:

- Sealed, reinforced housings that contain internal heat and sparks

- Certified electrical components tested to meet ATEX, IECEx, NEC, and UL standards

- Temperature and spark containment designed for classified hazardous areas

- Durable, corrosion-resistant materials to withstand harsh chemical exposure

These features ensure continuous, safe operation while maintaining full compliance with safety regulations.

Corrosion-Resistant Construction

Chemical manufacturing environments can be highly corrosive. Explosion proof cameras are made from stainless steel with specialized coatings to protect against damage from harsh chemicals, extending equipment lifespan and reducing maintenance requirements.

High-Definition Imaging

Having cameras that capture reliable footage is essential for real-time oversight and incident prevention in hazardous environments. Clear, high-resolution video helps operators monitor production lines, detect leaks, and verify safety procedures.

Remote Monitoring and Integration

Many modern explosion proof cameras can integrate with existing VMS platforms, allowing personnel to monitor operations remotely from control rooms or offsite locations. This reduces personnel exposure to high-risk zones while maintaining operational oversight.

Advanced Analytics and Smart Detection

Many explosion proof cameras for chemical manufacturing include intelligent analytics to improve safety and efficiency, such as:

- Motion detection for unauthorized access

- Intrusion alerts for security breaches

- Process monitoring to track chemical reactions or production flow

- Safety compliance verification to ensure adherence to operational protocols

These camera features provide robust surveillance, improve worker safety, and help maintain compliance across a wide range of hazardous environments.

Certifications & Compliance for Explosion Proof Cameras

Chemical manufacturing plants must meet strict safety regulations to protect workers, equipment, and facilities. Explosion proof cameras help ensure compliance by meeting internationally recognized hazardous area standards and preventing ignition in flammable environments.

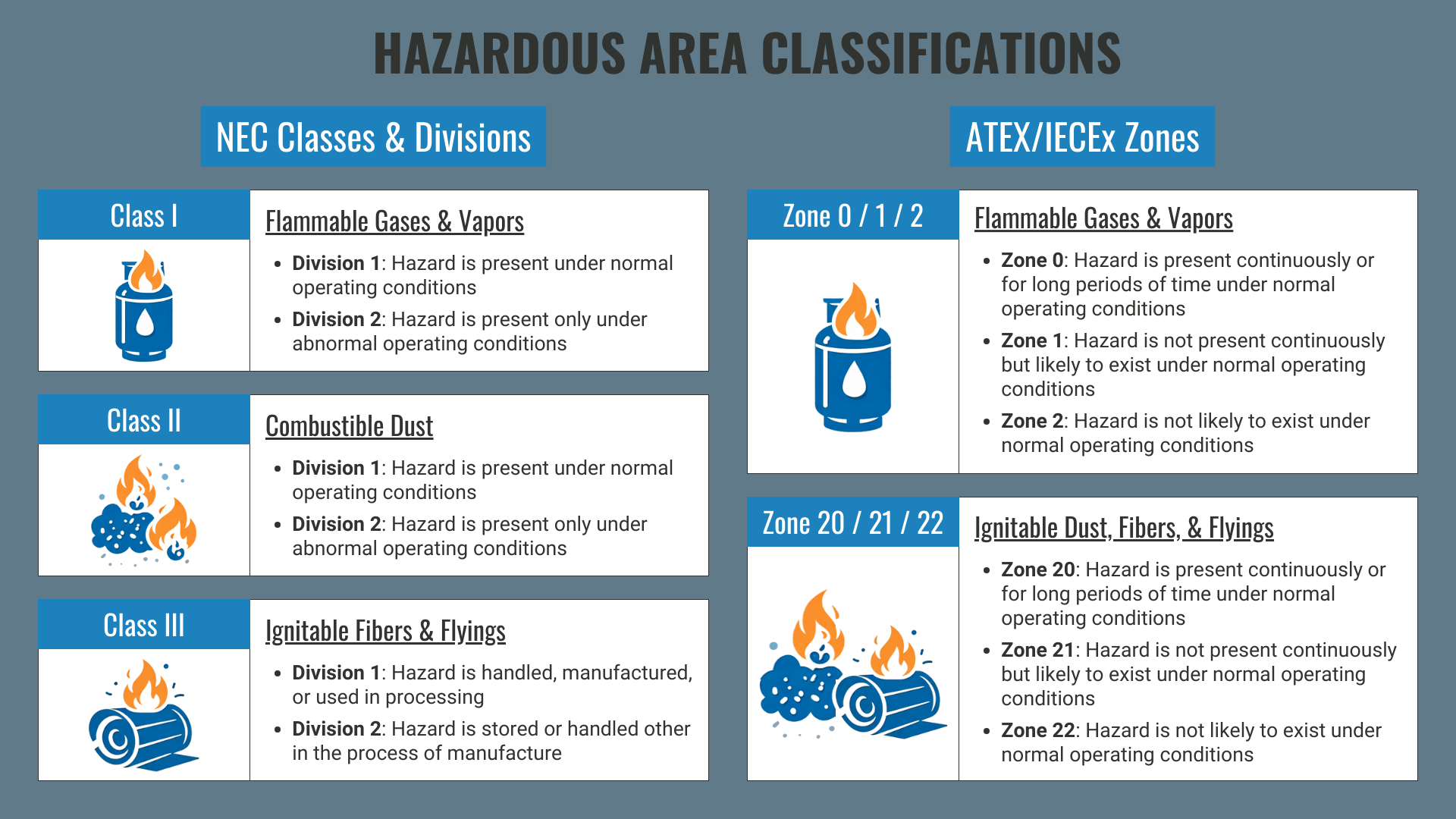

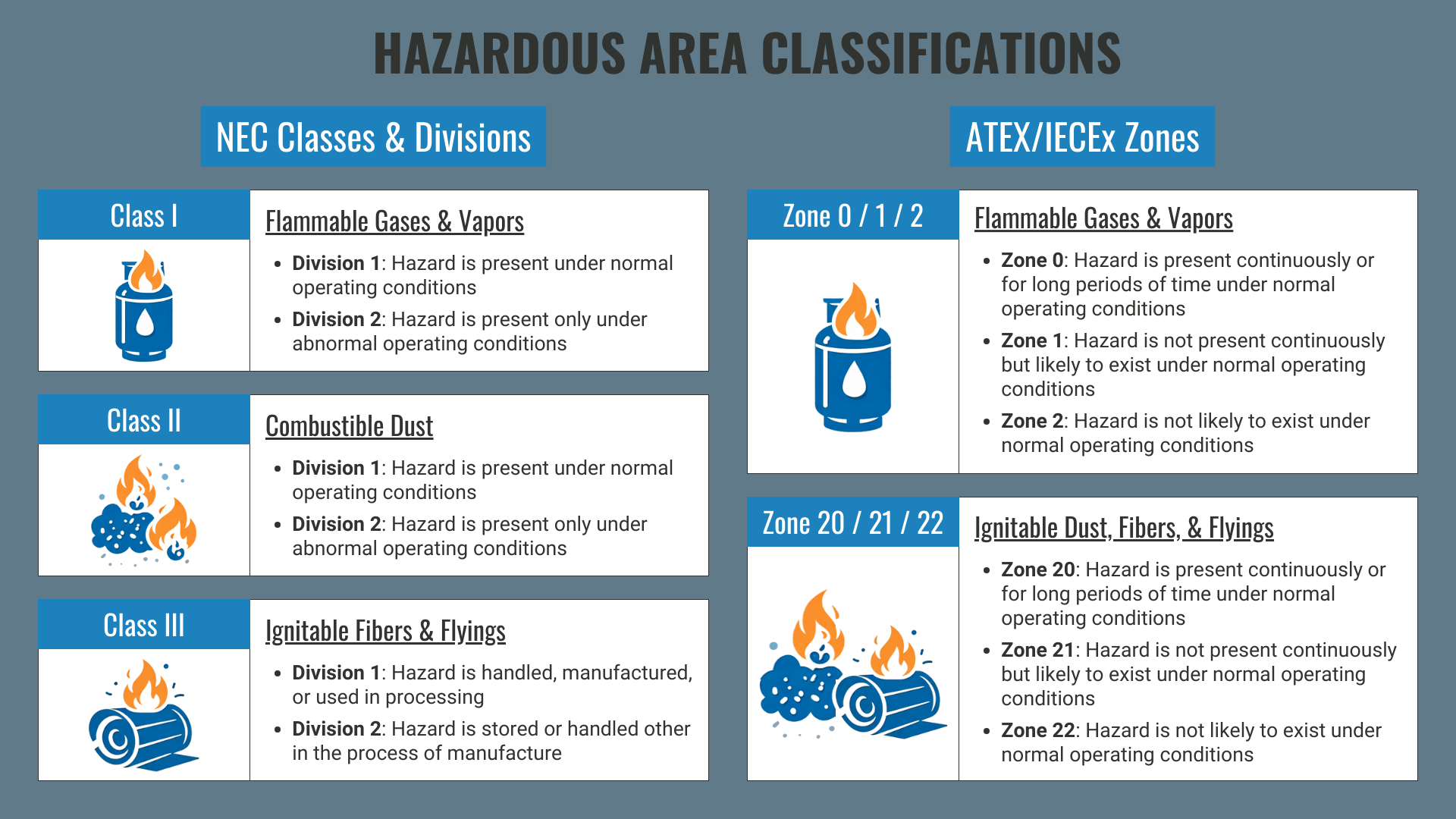

Key certifications and standards include:

- ATEX: European Union directive outlining equipment requirements and protection levels for operation in explosive atmospheres

- IECEx: Globally recognized certification for equipment designed for hazardous and explosive environments

- NEC: U.S. National Electrical Code system that classifies hazardous locations involving flammable gases, vapors, and combustible dust

- UL: Independent safety certification verifying compliance with NEC and U.S. hazardous location standards

- IP (Ingress Protection) Code: International classification system that measures resistance to dust and water intrusion

- NEMA Enclosure Types: U.S. standards that define the level of environmental protection provided by electrical enclosures

Choosing cameras with these certifications ensures that internal sparks, heat, or electrical faults are fully contained, preventing ignition and supporting compliance with workplace safety regulations.

Where Explosion Proof Cameras Are Installed in Chemical Manufacturing Plants

Strategic placement ensures both safety and operational visibility. Common installation areas of explosion proof cameras for chemical manufacturing facilities include:

- Mixing and blending stations

- Hazardous storage rooms

- Tank farms and chemical storage yards

- Filling and packaging lines

- Loading docks and transfer points

- Laboratory and testing areas

- Hazardous waste handling zones

By installing explosion proof cameras in these areas, staff can oversee operations from a safe distance and limit physical exposure to dangerous chemicals.

Choosing the Right Explosion Proof Camera

Every chemical facility has different hazards and operational needs. When selecting an explosion-proof camera system, consider:

- Hazard classification (Zone or Class rating)

- Environmental exposure (chemicals, corrosion, temperature)

- Indoor vs. outdoor installation

- Integration with existing security systems

- Remote monitoring needs

- Lighting conditions and image quality

Working with an experienced provider helps ensure your cameras meet both safety and operational goals.

Improving Safety in the Chemical Manufacturing Industry with Explosion-Proof Cameras

From paint and coatings facilities to pharmaceutical labs and petrochemical processing plants, hazardous environments require specialized surveillance solutions. Explosion proof cameras for chemical manufacturing plants provide reliable monitoring while protecting workers, equipment, and facilities from ignition risks.

By investing in certified hazardous-area surveillance for your chemical manufacturing facility, you can improve safety, maintain compliance, and gain real-time visibility into critical operations. Contact our team today at +1 (214) 988-4302 or sales@2mtechnology.net to discuss your security needs and receive a customized explosion-proof camera solution tailored to your facility.

Frequently Asked Questions (FAQs)

1. What are explosion proof cameras for chemical manufacturing facilities?

Explosion proof cameras for chemical manufacturing plants are specially designed surveillance cameras built to operate safely in hazardous areas with flammable gases, vapors, or combustible dust.

2. Do explosion-proof cameras prevent explosions in chemical manufacturing?

No. They are designed to contain internal sparks or heat so the camera does not ignite flammable gases, vapors, or combustible dust in hazardous chemical environments.

3. What hazardous area classifications are common in the chemical manufacturing industry?

Many facilities include NEC Class I Division 1 or Division 2 areas, ATEX Zone 1 or Zone 2 locations, and sometimes Class II areas with combustible dust.

4. How do explosion-proof cameras improve OSHA and safety compliance?

They provide visual monitoring that supports safety procedures, incident investigations, worker training, and compliance documentation in hazardous chemical operations.

5. Can explosion-proof cameras be used to monitor chemical reactions remotely?

Yes. Explosion-proof cameras allow operators to observe processes from control rooms, reducing their exposure to hazardous materials and dangerous incidents.

6. Are explosion-proof cameras resistant to corrosive chemicals?

Most explosion proof cameras use stainless steel housings with protective coatings to withstand corrosive conditions found in chemical and pharmaceutical manufacturing.

7. Are explosion-proof cameras required in paint manufacturing facilities?

Many paint production areas are classified hazardous locations due to the flammable nature of paints and solvents, making certified explosion-proof surveillance equipment strongly recommended (and in some cases, legally required) for safe monitoring.

8. Does 2M Technology offer explosion proof cameras for chemical manufacturing facilities?

Absolutely. At 2M Technology, we offer off-the-shelf explosion-proof cameras, or we can design and manufacture a custom explosion-proof housing for your specific camera model or brand. Contact our sales team to discuss your security needs and receive a customized pricing estimate. You can email sales@2mtechnology.net, call +1 (214) 988-4302, or fill out a quick quote form.

The chemical manufacturing industry includes some of the most hazardous workplaces in the world. Facilities that produce paint, coatings, resins, solvents, pharmaceuticals, or industrial chemicals often contain flammable vapors, combustible dust, and volatile gases. Standard security cameras are not designed for these conditions and can create serious safety risks.

Explosion proof cameras for chemical manufacturing facilities are specifically made to operate safely in classified hazardous areas while delivering clear, reliable video surveillance. These specialized cameras allow chemical manufacturers to monitor production processes, improve worker safety, and meet regulatory regulations without introducing potential ignition sources.

Why Explosion Proof Cameras for Chemical Manufacturing Are Necessary

Many chemical processes involve hazardous materials that can ignite when exposed to heat or sparks, both of which can be emitted by standard electrical equipment. Without proper containment, internal sparks or heat could come into contact with flammable gases, vapors, or combustible dust. Regular cameras are not designed to contain these ignition sources, making them unsafe for use in classified hazardous areas.

Explosion proof cameras for chemical manufacturing are built with sealed, reinforced housings and certified components that contain any internal sparks or heat, preventing them from affecting the surrounding environment.

Key Benefits of Explosion Proof Cameras for Chemical Manufacturing

- Safer monitoring in hazardous zones

- Continuous surveillance in flammable environments

- Improved accident prevention and faster incident response

- Compliance with ATEX, IECEx, and NEC/UL standards

- Reduced downtime and operational risks

By installing explosion proof cameras for chemical manufacturing plants, companies can maintain operational visibility while protecting workers, equipment, and facilities.

Chemical Manufacturing Industries That Use Explosion Proof Cameras

Explosion-proof cameras are essential across many chemical manufacturing sectors. While paint manufacturing is a major example, other industries also rely on these cameras, each with unique hazards and monitoring needs.

Paint and Coatings Manufacturing

Paint production involves solvents, pigments, and flammable liquids. Cameras help monitor mixing stations, storage tanks, and filling lines while reducing the need for personnel to enter high-risk zones.

Pharmaceutical and Chemical Processing

Facilities producing active pharmaceutical ingredients (APIs) and specialty chemicals may use volatile solvents or powders. Explosion proof cameras allow operators to safely monitor reactions, packaging, and storage.

Petrochemical and Refining Operations

Petrochemical plants handle highly flammable hydrocarbons. Certified cameras help monitor pipelines, storage tanks, and processing equipment in hazardous classified areas.

Resin and Adhesive Manufacturing

Resin and adhesive production involves chemical reactions and combustible materials. Cameras provide visibility into production areas while minimizing worker exposure.

Industrial Solvent and Cleaning Chemical Production

Solvent manufacturing presents serious explosion risks due to vapor accumulation. Explosion-proof cameras improve safety monitoring and ensure regulatory compliance.

Fertilizer and Agricultural Chemical Facilities

Certain fertilizers and agricultural chemicals contain combustible dust or reactive compounds. Cameras help detect hazards early and support operational oversight.

Specialty Chemical Manufacturing

Producers of dyes, additives, polymers, and laboratory chemicals often require precise monitoring in confined hazardous environments.

Key Features of Explosion Proof Cameras for Chemical Manufacturing Plants

Not all hazardous-area cameras are the same. When selecting explosion proof cameras for chemical manufacturing, companies should focus on features that improve both safety and operational efficiency while providing reliable monitoring in high-risk environments.

Certified Hazardous Area Protection

Explosion proof cameras are built with sealed housings and components that prevent sparks, heat, or electrical faults from igniting flammable materials. Key features include:

- Sealed, reinforced housings that contain internal heat and sparks

- Certified electrical components tested to meet ATEX, IECEx, NEC, and UL standards

- Temperature and spark containment designed for classified hazardous areas

- Durable, corrosion-resistant materials to withstand harsh chemical exposure

These features ensure continuous, safe operation while maintaining full compliance with safety regulations.

Corrosion-Resistant Construction

Chemical manufacturing environments can be highly corrosive. Explosion proof cameras are made from stainless steel with specialized coatings to protect against damage from harsh chemicals, extending equipment lifespan and reducing maintenance requirements.

High-Definition Imaging

Having cameras that capture reliable footage is essential for real-time oversight and incident prevention in hazardous environments. Clear, high-resolution video helps operators monitor production lines, detect leaks, and verify safety procedures.

Remote Monitoring and Integration

Many modern explosion proof cameras can integrate with existing VMS platforms, allowing personnel to monitor operations remotely from control rooms or offsite locations. This reduces personnel exposure to high-risk zones while maintaining operational oversight.

Advanced Analytics and Smart Detection

Many explosion proof cameras for chemical manufacturing include intelligent analytics to improve safety and efficiency, such as:

- Motion detection for unauthorized access

- Intrusion alerts for security breaches

- Process monitoring to track chemical reactions or production flow

- Safety compliance verification to ensure adherence to operational protocols

These camera features provide robust surveillance, improve worker safety, and help maintain compliance across a wide range of hazardous environments.

Certifications & Compliance for Explosion Proof Cameras

Chemical manufacturing plants must meet strict safety regulations to protect workers, equipment, and facilities. Explosion proof cameras help ensure compliance by meeting internationally recognized hazardous area standards and preventing ignition in flammable environments.

Key certifications and standards include:

- ATEX: European Union directive outlining equipment requirements and protection levels for operation in explosive atmospheres

- IECEx: Globally recognized certification for equipment designed for hazardous and explosive environments

- NEC: U.S. National Electrical Code system that classifies hazardous locations involving flammable gases, vapors, and combustible dust

- UL: Independent safety certification verifying compliance with NEC and U.S. hazardous location standards

- IP (Ingress Protection) Code: International classification system that measures resistance to dust and water intrusion

- NEMA Enclosure Types: U.S. standards that define the level of environmental protection provided by electrical enclosures

Choosing cameras with these certifications ensures that internal sparks, heat, or electrical faults are fully contained, preventing ignition and supporting compliance with workplace safety regulations.

Where Explosion Proof Cameras Are Installed in Chemical Manufacturing Plants

Strategic placement ensures both safety and operational visibility. Common installation areas of explosion proof cameras for chemical manufacturing facilities include:

- Mixing and blending stations

- Hazardous storage rooms

- Tank farms and chemical storage yards

- Filling and packaging lines

- Loading docks and transfer points

- Laboratory and testing areas

- Hazardous waste handling zones

By installing explosion proof cameras in these areas, staff can oversee operations from a safe distance and limit physical exposure to dangerous chemicals.

Choosing the Right Explosion Proof Camera

Every chemical facility has different hazards and operational needs. When selecting an explosion-proof camera system, consider:

- Hazard classification (Zone or Class rating)

- Environmental exposure (chemicals, corrosion, temperature)

- Indoor vs. outdoor installation

- Integration with existing security systems

- Remote monitoring needs

- Lighting conditions and image quality

Working with an experienced provider helps ensure your cameras meet both safety and operational goals.

Improving Safety in the Chemical Manufacturing Industry with Explosion-Proof Cameras

From paint and coatings facilities to pharmaceutical labs and petrochemical processing plants, hazardous environments require specialized surveillance solutions. Explosion proof cameras for chemical manufacturing plants provide reliable monitoring while protecting workers, equipment, and facilities from ignition risks.

By investing in certified hazardous-area surveillance for your chemical manufacturing facility, you can improve safety, maintain compliance, and gain real-time visibility into critical operations. Contact our team today at +1 (214) 988-4302 or sales@2mtechnology.net to discuss your security needs and receive a customized explosion-proof camera solution tailored to your facility.

Frequently Asked Questions (FAQs)

1. What are explosion proof cameras for chemical manufacturing facilities?

Explosion proof cameras for chemical manufacturing plants are specially designed surveillance cameras built to operate safely in hazardous areas with flammable gases, vapors, or combustible dust.

2. Do explosion-proof cameras prevent explosions in chemical manufacturing?

No. They are designed to contain internal sparks or heat so the camera does not ignite flammable gases, vapors, or combustible dust in hazardous chemical environments.

3. What hazardous area classifications are common in the chemical manufacturing industry?

Many facilities include NEC Class I Division 1 or Division 2 areas, ATEX Zone 1 or Zone 2 locations, and sometimes Class II areas with combustible dust.

4. How do explosion-proof cameras improve OSHA and safety compliance?

They provide visual monitoring that supports safety procedures, incident investigations, worker training, and compliance documentation in hazardous chemical operations.

5. Can explosion-proof cameras be used to monitor chemical reactions remotely?

Yes. Explosion-proof cameras allow operators to observe processes from control rooms, reducing their exposure to hazardous materials and dangerous incidents.

6. Are explosion-proof cameras resistant to corrosive chemicals?

Most explosion proof cameras use stainless steel housings with protective coatings to withstand corrosive conditions found in chemical and pharmaceutical manufacturing.

7. Are explosion-proof cameras required in paint manufacturing facilities?

Many paint production areas are classified hazardous locations due to the flammable nature of paints and solvents, making certified explosion-proof surveillance equipment strongly recommended (and in some cases, legally required) for safe monitoring.

8. Does 2M Technology offer explosion proof cameras for chemical manufacturing facilities?

Absolutely. At 2M Technology, we offer off-the-shelf explosion-proof cameras, or we can design and manufacture a custom explosion-proof housing for your specific camera model or brand. Contact our sales team to discuss your security needs and receive a customized pricing estimate. You can email sales@2mtechnology.net, call +1 (214) 988-4302, or fill out a quick quote form.