When it comes to explosion proof cameras, there’s no single model or brand that’s best for every situation. The “best” custom explosion proof camera is the one designed specifically to fit your hazardous site’s conditions, operational needs, and safety requirements. At 2M Technology, we create custom explosion proof housings that transform any camera model you choose into a safe and compliant surveillance solution. Instead of settling for off-the-shelf options, you can take a camera you already trust and have it custom-fitted with an explosion-proof housing, making it safe for use in any hazardous work site.

What Is a Custom Explosion Proof Camera?

A custom explosion proof camera is a standard security camera enclosed in a special housing that makes it safe to use in hazardous areas where flammable gases, vapors, or dust are present. The purpose of this housing is to contain any sparks, heat, or internal malfunctions from the camera, preventing them from igniting the potentially explosive atmosphere around it.

What makes a custom explosion proof camera truly custom is the housing that is tailored to fit any camera you choose. This means you’re not limited to a small selection of camera models. You can pick any camera and we’ll built an explosion-proof housing around it. This gives you the flexibility to use the exact camera model and features your operations require without compromising safety or compliance.

With 2M Technology, you get more than just an explosion proof camera. You get a surveillance system that’s customized to your operational goals, environmental challenges, and safety requirements, using high-performance cameras protected by rugged, certified enclosures.

What Is the Best Custom Explosion Proof Camera?

So, which custom explosion proof camera is the best? The best custom explosion proof camera is one that is made specifically for your hazardous location. Instead of picking a pre-packaged model, the ideal solution combines the camera features you need with a housing designed to withstand your site’s risks. Here’s what to consider when choosing the best custom explosion proof camera for your operations:

1. Site Classification and Certifications

Not all hazardous areas are the same. Some are filled with flammable gases, others with combustible dust, and the frequency and intensity of these risks vary by location. Because of this, strict regulations determine what type of equipment can be installed in each classified zone. Failure to comply with these standards not only puts you at legal risk, it also endangers your facility, operations, and personnel. That’s why it’s critical to make sure your custom explosion proof camera is properly rated for your specific area, whether that’s Class I Division 1, Zone 1, or Zone 2.

2. Camera Model and Features

When choosing a camera, start by evaluating your imaging needs and what you need to monitor. The lens type determines both the coverage area and the level of detail in your footage. Wide-angle lenses are perfect for monitoring large open spaces like tank farms, while zoom lenses are ideal for close-up views of machinery in high-risk areas. If your site has poor visibility due to smoke, dust, or darkness, thermal or dual-spectrum imaging can detect heat signatures to help spot overheating machinery, gas leaks, or intruders. A custom explosion proof camera housing preserves the camera’s full functionality while protecting it from hazardous conditions. This means the camera performs exactly as intended, but without compromising safety.

3. Housing Material and Durability

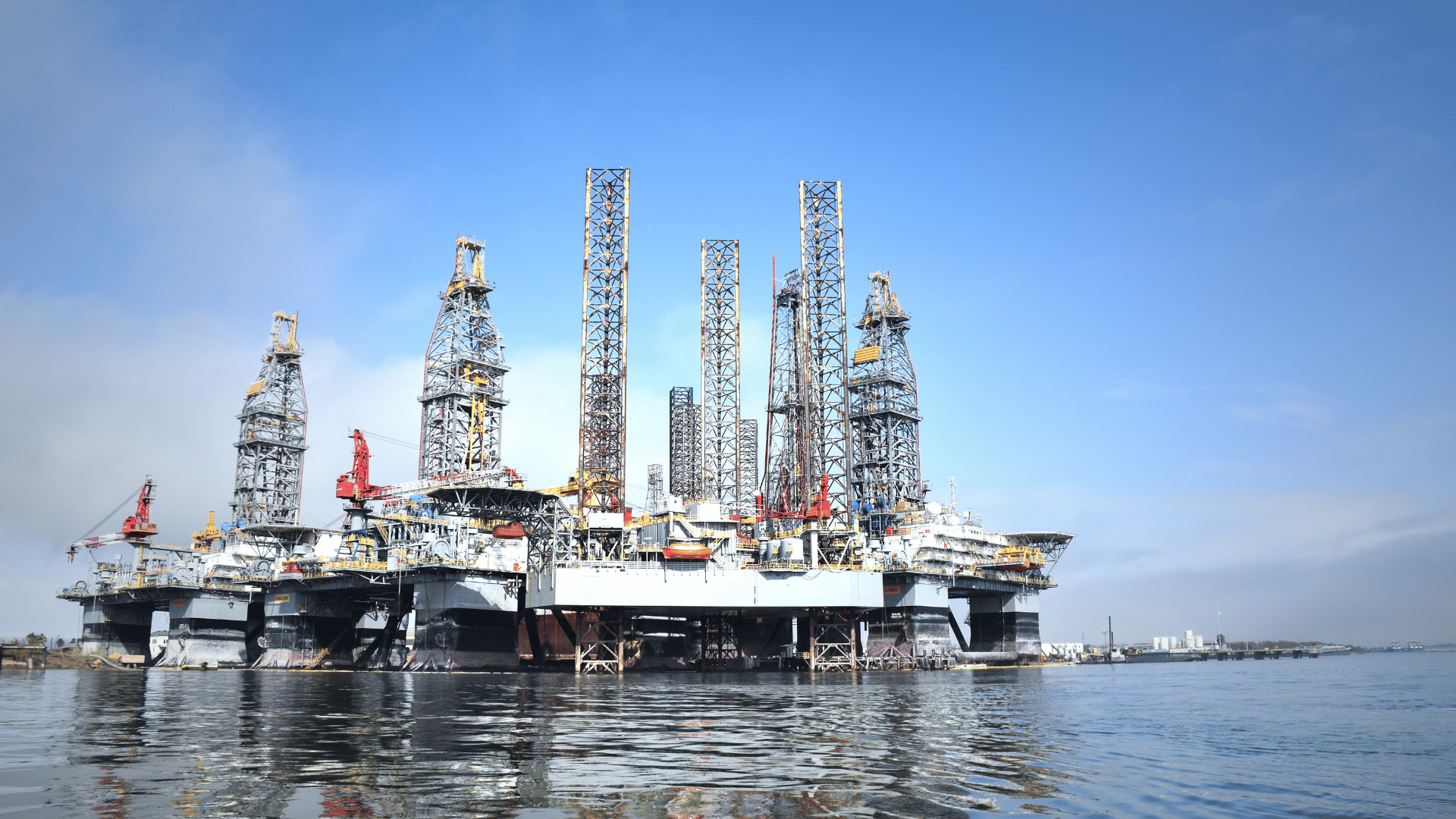

The material of your camera housing affects how well your camera will be protected from harsh environments and potential ignition sources. At 2M, we offer two options: 304 stainless steel and 316L stainless steel. For general industrial settings with minimal to moderate exposure to corrosive elements, 304 stainless steel is usually durable enough. But in harsher environments, like offshore rigs or chemical plants, 316L stainless steel offers stronger resistance to corrosion from salt, chemicals, and extreme weather. Choosing the right housing material not only extends the life of your custom explosion proof camera but also ensures it won’t fail even in the toughest environments.

4. Power and Connectivity Considerations

Power and networking setups vary from site to site. Some operations run on PoE (Power over Ethernet), while others rely on fiber, coaxial, or custom cabling. Your custom explosion proof camera housing should include properly sized and sealed cable glands or conduit fittings that match the connection types your site uses. These openings are essential for maintaining the enclosure’s explosion-proof integrity and ensuring your system operates safely and reliably, all without limiting installation flexibility.

Why Choose 2M Technology?

The “best” explosion proof camera is one that works perfectly for your site’s specific conditions and compliance needs. At 2M Technology, we don’t believe in one-size-fits-all solutions. Every industrial site is unique, so we work closely with you to design a custom explosion proof camera that fulfills your camera preferences, complies with your site classification, and holds up in your operating conditions.

You’re free to choose any camera model, and we’ll create a housing that makes it safe, compliant, and durable enough to handle your location’s demands. The result is a fully functional surveillance solution with certified protection, customized just for your site.

Ready to Build Your Custom Explosion Proof Camera?

If you’re searching for the best custom explosion proof camera for your hazardous location, you can find it at 2M Technology. We’ll help you build a solution that not only protects your site but also meets all necessary certifications and standards. Get started today with a free quote by contacting us at sales@2mtechnology.net or +1 (214) 988-4302.