When choosing surveillance equipment for hazardous areas, it’s important to understand the risks involved. Areas such as oil refineries, chemical plants, grain silos, and mining facilities may contain flammable gases, combustible dust, or ignitable fibers. If the wrong type of electrical equipment is used, these materials can easily ignite and cause dangerous explosions. To ensure safety, all equipment must be properly certified and rated for use in that specific hazardous location.

This guide explains the major certification systems and breaks down the meanings behind their explosion proof ratings so you can choose the right equipment with confidence.

What Are Explosion Proof Ratings?

Not all hazardous areas are the same, and equipment that’s safe in one environment may not be safe in another. To account for this, global safety organizations have developed certification systems that regulate how equipment is built, tested, and marked for use in explosive atmospheres.

The three most widely accepted explosion-proof certification systems are:

- NEC/UL – used in the United States and Canada

- ATEX – required in the European Union

- IECEx – recognized by many countries worldwide

Each system has its own markings, classifications, and safety standards that define the type of hazard, how often it occurs, and how equipment must be designed to safely operate in that environment.

NEC/UL Certification (North America)

In the U.S., hazardous location equipment is certified according to the National Electrical Code (NEC) and tested by organizations like Underwriters Laboratories (UL). This system for explosion proof ratings uses Classes, Divisions, Groups, and Temperature Codes (T-Codes) to describe the type of hazard in the area and how often it occurs.

- Class: The general type of hazard present.

- Division: How often the hazardous substance is present.

- Group: The specific type of gas, dust, or fibers in the area.

- Temperature Class (T-Code): The maximum temperature the equipment’s surface can reach. It must be lower than the ignition temperature of the hazardous material in the area.

| Class | Division | Group | T-Code |

|---|---|---|---|

| I: Flammable gases or vapors | 1: Hazard is present under normal operating conditions 2: Hazard is present only under abnormal conditions |

A: Acetylene B: Hydrogen, Butadiene, Ethylene Oxide, Propylene Oxide, Acrolein C: Ethylene, Cyclopropane, Ethyl Ether D: Acetone, Ammonia, Benzene, Butane, Ethanol, Gasoline, Hexane, Methane, Methanol, Naphtha, Natural Gas, Propane, Toluene |

T1: 450°C (842°F) T2: 300°C (572°F) T3: 200°C (392°F) T4: 135°C (275°F) T5: 100°C (212°F) T6: 85°C (185°F)* |

| II: Combustible dust | 1: Hazard is present under normal operating conditions 2: Hazard is present only under abnormal conditions |

E: Conductive Metal Dusts (Aluminum, Commercial Alloys, Magnesium) F: Carbonaceous Dusts (Carbon Black, Charcoal, Coal, Coke Dust) G: Non-Conductive Dusts (Grain Dust, Starch, Flour, Plastics, Wood Dust, Chemicals) |

|

| III: Ignitable fibers or flyings | 1: Hazard is handled, manufactured, or used in processing 2: Hazard is stored or handled other than in the process of manufacture |

No Groups (Cotton, Rayon, Sawdust, Wood Chips, Textiles) |

ATEX Certification (European Union)

ATEX stands for “ATmosphères EXplosibles,” and it refers to the European Union certification system that is mandatory for any equipment used in explosive atmospheres. ATEX uses several categories and codes to define the type of explosive substance present, how often it occurs, the level of danger, and how the equipment is designed to prevent ignition. Here’s a simple breakdown of what each part of ATEX’s explosion proof ratings means:

- Zone: How often the hazardous substance is present.

- Equipment Group: The industry where the equipment will be used.

- Equipment Category: How much protection is needed, depending on the risk level in the area.

- Environment: What type of hazard is present.

- Protection Method (Ex Code): The way the equipment is engineered to prevent sparks or flames.

- Group: The specific type of explosive material.

- Temperature Class: The maximum temperature the equipment’s surface can reach. This must be lower than the ignition point of the surrounding hazardous material.

- EPL (Equipment Protection Level): The level of safety based on how likely the equipment is to cause ignition.

| Equipment Group | Equipment Category | Environment | Protection Method (Ex Code) |

Group | Temperature Class | EPL | Zone |

|---|---|---|---|---|---|---|---|

| I: Mining | M1: Very high protection | Ex d: Flameproof Ex e: Increased safety Ex i: Intrinsic safety Ex ia: Intrinsically safe (Zone 0) Ex m: Encapsulation Ex p: Pressurization Ex t: Dust-tight Ex n: Non-sparking (Zone 2) |

I: Firedamp | Ma: Very high protection | |||

| M2: High protection | Mb: High protection | ||||||

| II: Surface industries | 1: Very high protection | G: Gas | IIA: Propane IIB: Ethylene IIC: Hydrogen/Acetylene |

T1: 450°C T2: 300°C T3: 200°C T4: 135°C T5: 100°C T6: 85°C |

Ga: Very high protection | Zone 0: Hazard is present continuously or for long periods of time under normal operating conditions | |

| 2: High protection | Gb: High protection | Zone 1: Hazard is not present continuously but likely to occur under normal operating conditions | |||||

| 3: Normal protection | Gc: Normal protection | Zone 2: Hazard is not likely to occur under normal operating conditions but could for short periods of time | |||||

| 1: Very high protection | D: Dust | IIIA: Fibers/flyings IIIB: Non-conductive dust IIIC: Conductive dust |

T450°C: 450°C T300°C: 300°C T200°C: 200°C T135°C: 135°C T100°C: 100°C T85°C: 85°C |

Da: Very high protection | Zone 20: Hazard is present continuously or for long periods of time under normal operating conditions | ||

| 2: High protection | Db: High protection | Zone 21: Hazard is not present continuously but likely to occur under normal operating conditions | |||||

| 3: Normal protection | Dc: Normal protection | Zone 22: Hazard is not likely to occur under normal operating conditions but could for short periods of time |

IECEx Certification (International)

IECEx is a global certification system developed by the International Electrotechnical Commission (IEC) for equipment used in explosive environments. Although it follows the same rating structure as ATEX, it is not tied to EU regulations. Instead, IECEx is a voluntary certification that verifies equipment meets international safety standards. It’s widely accepted in many countries, including Australia, Canada, South Africa, and parts of Asia and the Middle East.

IECEx explosion proof ratings are almost identical to ATEX but do not include the Equipment Group, Equipment Category, or Environment directly. However, this information can be easily determined from the other markings on the label.

Why Do These Explosion Proof Ratings Matter?

Explosion-proof certifications are more than just regulatory requirements; they’re essential for protecting people, property, and operations in high-risk environments. In hazardous zones where flammable gases, dust, or fibers are present, even a small electrical spark can trigger a devastating explosion. That’s why any electrical equipment used in these areas must meet strict explosion-proof standards to ensure it won’t ignite dangerous substances under any conditions.

Explosion proof ratings ensure that electrical equipment is not only safe to use but can also handle the specific conditions of the hazardous area it’s installed in. They confirm that the equipment has been rigorously designed, built, and tested to prevent ignition under the exact environmental conditions it will face.

Need Help Choosing the Right Explosion-Proof Equipment?

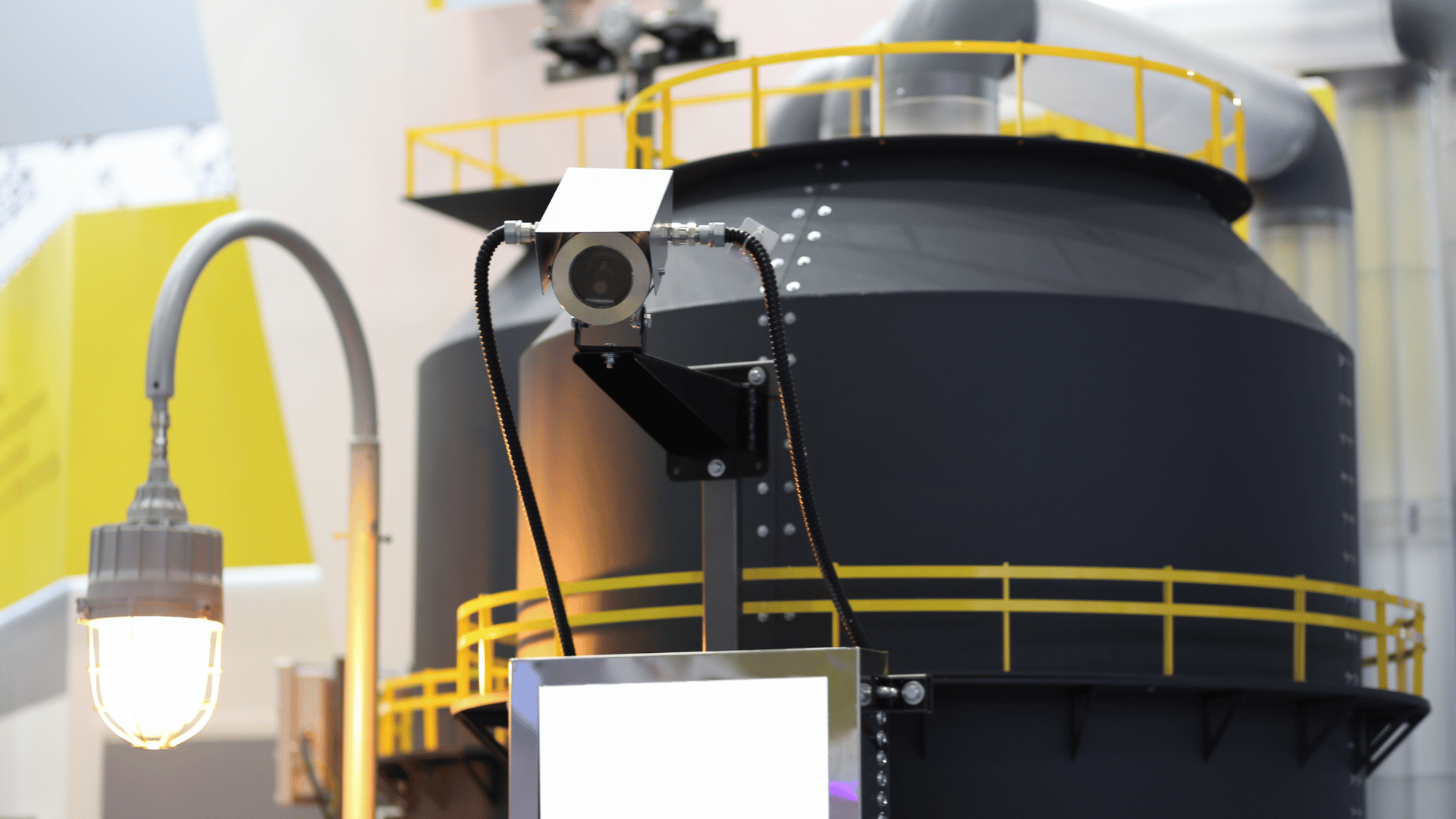

When you choose an explosion-proof camera from 2M Technology, you’re getting a solution that’s been certified to meet NEC/UL, ATEX, or IECEx standards—and more importantly, one that’s tailored to the real-world risks of your site.

Whether you’re in North America, Europe, or serving international projects, our team can help you select a certified, custom-built explosion-proof surveillance system that fits your environment and safety needs. Contact us today to get started at (214) 988-4302 or email sales@2mtechnology.net.