Industries that handle flammable gases, combustible dust, or volatile chemicals always face the risk of explosions. Because of this, they must use electrical equipment made to prevent ignition. But every worksite has different risks, and what’s safe in one place might not be safe in another. That’s why safety organizations have developed systems to classify hazardous areas. These classifications help define risks and guide the design of equipment that can be safely used in those areas. In this blog, we’ll explain the main classification systems and review common hazardous area classifications by industry.

What Is a Hazardous Area?

A hazardous area is any location where flammable gases, vapors, dust, or fibers might be present in amounts high enough to cause an explosion. To prevent sparks or ignition, all electrical and electronic equipment used in these areas must be specially designed and certified to be safe.

How Are Hazardous Areas Classified?

There are three main systems used worldwide to classify hazardous areas:

-

NEC/UL (Class & Division System): Common in the U.S. and Canada

-

ATEX: Required in the European Union

-

IECEx: An international standard recognized in many countries

At a basic level, all these systems group hazardous locations based on two things: the type of explosive material present and how likely it is to be there.

| Hazard Type | NEC/UL Class | NEC/UL Division | Frequency of Hazard | ATEX/IECEx Zone |

|---|---|---|---|---|

| Flammable gases/vapors | Class I | Division 1 | Hazard is present continuously or for long periods of time under normal operating conditions | Zone 0 |

| Hazard is not present continuously but likely to occur under normal operating conditions | Zone 1 | |||

| Division 2 | Hazard is not likely to occur under normal operating conditions but could for short periods of time | Zone 2 | ||

| Combustible dust | Class II | Division 1 | Hazard is present continuously or for long periods of time under normal operating conditions | Zone 20 |

| Hazard is not present continuously but likely to occur under normal operating conditions | Zone 21 | |||

| Division 2 | Hazard is not likely to occur under normal operating conditions but could for short periods of time | Zone 22 | ||

| Ignitable fibers/flyings | Class III | Division 1 | Hazard is present continuously or for long periods of time under normal operating conditions | Zone 20 |

| Hazard is not present continuously but likely to occur under normal operating conditions | Zone 21 | |||

| Division 2 | Hazard is not likely to occur under normal operating conditions but could for short periods of time | Zone 22 |

Why Do Hazardous Area Classifications Matter?

Classifying hazardous areas helps determine the type of explosion-proof equipment required. Knowing your facility’s classification is essential for choosing safe and compliant equipment. The hazardous area classification tells you what kind of risk exists in a location, while the explosion-proof rating tells you what kind of equipment is safe and approved for use there.

Learning all the specific ratings can be complex, but you can usually get a general idea of your facility’s classification based on what you know about your industry and how your operations run. Factors like the type of hazard, how often it’s present, and the environment where equipment will be used all help gauge the level of risk. Having this general knowledge makes it easier to select the right equipment and communicate your needs with manufacturers or safety experts.

Common Hazardous Area Classifications by Industry

Below are some of the most common industries that handle hazardous materials, along with the hazardous area classifications they are likely to have.

Keep in mind, these classifications are general examples based on typical scenarios. Actual explosion-proof ratings for a specific facility can vary depending on factors like the exact processes used, materials handled, ventilation, and local rules. To get the correct rating, a professional site assessment is always needed.

Oil & Gas

The oil and gas industry often works with flammable gases such as methane, propane, and hydrogen sulfide. These gases are found in places like drilling rigs, refineries, compressor stations, and storage tanks. Because these gases may be present often or even all the time during normal work, oil and gas sites usually need the highest level of protection. This typically means Class I, Division 1 or 2 under the NEC system, or Zone 0, 1, or 2 in the Zone system.

Chemical & Petrochemical

Chemical and petrochemical plants handle volatile compounds, solvents, and vapors. These hazards are common in areas like chemical storage, distillation towers, and loading zones. The risk here is usually high but less constant than in oil and gas, so these facilities often fall under Class I, Division 1 or 2, or Zone 1 or 2 classifications.

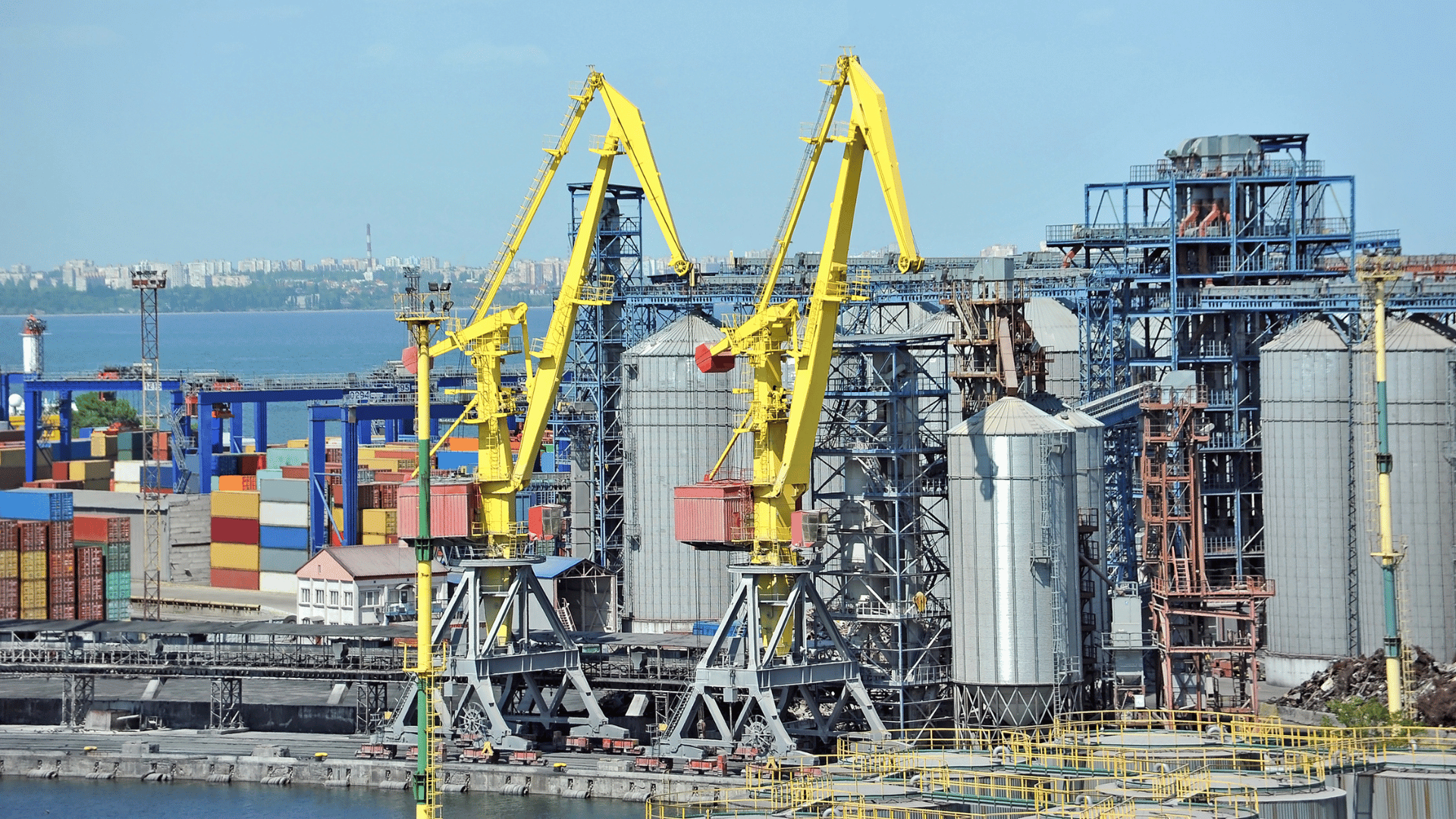

Agriculture & Food Processing

Agriculture and food processing industries deal mostly with combustible dust produced by materials like grain, flour, sugar, and starch. Hazardous spots include silos, grain elevators, mills, and sugar plants. Since dust clouds usually form only occasionally, these areas are generally classified as Class II, Division 1 or 2, or Zones 21 or 22.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing sites often handle alcohol vapors, fine powders, and solvent fumes during processes like coating, solvent storage, and chemical mixing. Because these hazardous substances are present mostly during certain operations or in designated rooms rather than constantly, their classifications can range from Class I or II, Division 1 or 2, to Zones 1/21 or 2/22.

Water & Wastewater Treatment

Water and wastewater treatment plants generate hazardous gases such as methane, hydrogen sulfide, and chlorine gas, especially in wet wells, digesters, and sludge handling areas. These gases can be produced intermittently or, in some cases, continuously, so these areas are typically classified as Class I, Division 1 or 2, or Zone 1 or 2.

Woodworking & Paper Processing

Woodworking and paper processing facilities face risks from combustible wood dust and paper fibers, especially near dust collection systems and processing machines. Dust clouds in these settings tend to form sporadically rather than constantly, so they usually fall under Class III for fibers, Class II for dust, Division 1 or 2, or Zones 21 or 22.

You Know Your Industry, We Know the Ratings

If you need explosion-proof equipment, we’re here to help. You don’t need to feel overwhelmed if you’re not familiar with terms like “Class I, Division 2” or “Zone 21.”

Just let us know:

-

What industry you work in

-

What kind of environment or materials are involved

-

Where the equipment will be used

From there, our team will figure out the correct explosion-proof rating and recommend a solution that fits your needs and meets all safety standards. We take the guesswork out of compliance so you can focus on running your operations safely and efficiently. Contact us today at +1 (214) 988-4302 or email sales@2mtechnology.net to get started.