Ubiquiti’s UniFi cameras are widely used for their ease of use, cloud integration, and smart design. They’re a popular choice for businesses looking for simple, scalable video surveillance. But even though they work well in office buildings, retail stores, and warehouses, they aren’t built for explosive environments. At 2M Technology, we design custom explosion-proof housings for Ubiquiti UniFi cameras, allowing you to use these cameras while preventing explosions in hazardous locations.

Why Are Ubiquiti UniFi Cameras Unsafe in Hazardous Areas?

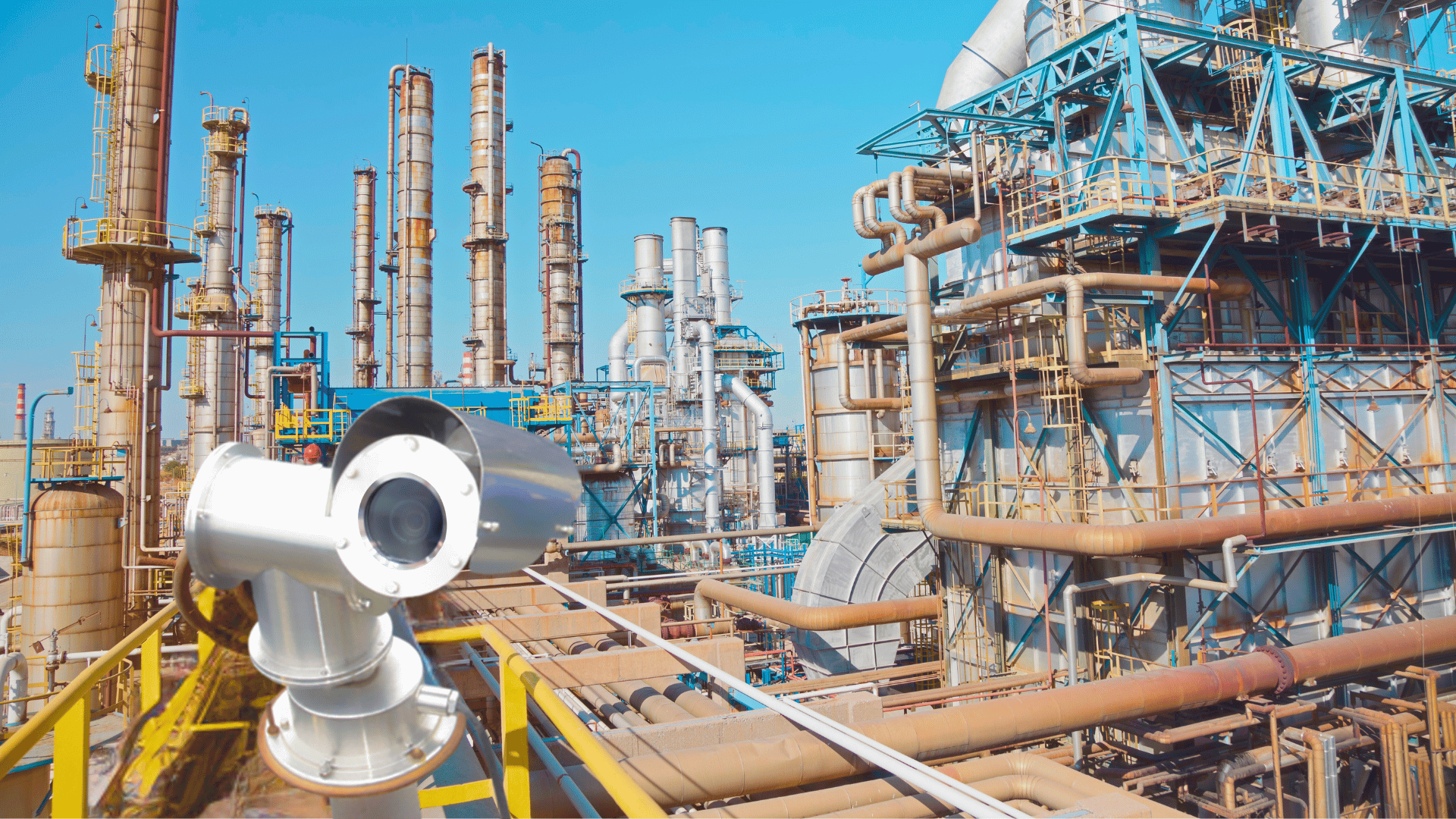

Ubiquiti UniFi cameras are great for general-purpose surveillance, but they aren’t designed for places like oil refineries, chemical plants, or grain processing facilities. These environments may contain flammable gases, vapors, or combustible dust, making the use of standard electronics a major safety risk.

The casings on UniFi cameras are not certified to prevent ignition, so even a small internal spark can trigger a deadly explosion. That’s why using explosion-proof housings for Ubiquiti UniFi cameras is essential when installing them in classified hazardous zones.

How Can You Make Ubiquiti UniFi Cameras Explosion-Proof?

To safely use Ubiquiti UniFi cameras in hazardous zones, they must be enclosed in special, sealed housings. These explosion-proof housings contain any internal heat or electrical discharge that could ignite the surrounding atmosphere.

At 2M Technology, we can specifically design these explosion-proof housings for Ubiquiti UniFi cameras. They are the safest, most cost-effective way to continue using the system you already rely on without violating safety regulations.

What Is a Custom Explosion-Proof Housing?

A custom explosion-proof housing is a rugged enclosure designed to match the exact specifications of your Ubiquiti UniFi camera. The housing is tightly sealed to keep any potential ignition sources produced by the camera, like sparks, heat, or flames, inside to prevent ignition of nearby explosive materials.

Each custom housing from 2M Technology is precision-built to fit the size and viewing angle of your UniFi camera model. This allows you to retain all the core camera functions, including night vision, wide-angle monitoring, and cloud-based access, while ensuring the camera is safely isolated from any explosive materials in the surrounding environment.

What Features Are Available for Our Custom Explosion-Proof Housings for Ubiquiti UniFi Cameras?

Each of our custom explosion-proof housings for Ubiquiti UniFi cameras is made from high-strength stainless steel and engineered for safe operation in extreme conditions. We make sure the housing fits securely around the camera, with careful attention to lens alignment, heat ventilation, and network cabling.

We can also incorporate optional features to help make the housing more resilient in harsh environments. Upgrades include:

- Integrated heaters for cold climates

- Built-in fans for high-temperature zones

- Sunshields for direct sunlight exposure

- Lens wipers for extreme humidity and condensation

- Corrosion-resistant coatings for chemical or salt air/water exposure

Depending on your requirements, we can provide certifications for use in Class I, Division 1 or 2 (NEC).

Is a Custom Housing Better Than Buying an Explosion-Proof Camera?

If you’re already using Ubiquiti UniFi cameras across your facility, replacing your entire system with new explosion-proof cameras can be expensive and disruptive. Using custom explosion-proof housings for Ubiquiti UniFi cameras lets you keep your current system while adding only what’s needed to make it safe.

You get the safety and compliance your site needs without losing the camera features, platform flexibility, or management tools of your existing Ubiquiti UniFi ecosystem. A custom housing is a smarter, more scalable solution for industrial environments that need to extend surveillance into hazardous areas without overhauling infrastructure.

What’s the Process for Getting a Custom Explosion-Proof Ubiquiti UniFi Camera Housing?

When you work with 2M Technology, you’re getting more than just a shell. From concept to delivery, we handle the entire process, which entails:

- Identifying your Ubiquiti UniFi camera model

- Assessing your site’s hazardous area classification and conditions

- Drafting a custom explosion-proof housing design based on the dimensions, specifications, and requirements

- Making any changes to the design until receiving your final approval

- Fabricating, assembling, and testing the housing

Each project is fully customized to your needs and backed by expert support throughout the process.

Start a Project Today

Switching to an explosion-proof camera system doesn’t have to mean starting over. With custom explosion-proof housings for Ubiquiti UniFi cameras, you can expand your surveillance coverage into high-risk zones without compromising performance or compliance. You get to keep the system you know while gaining full peace of mind knowing it’s protected and safe for hazardous areas. To get started, contact 2M Technology for a quote or design consultation: