Features

Overview

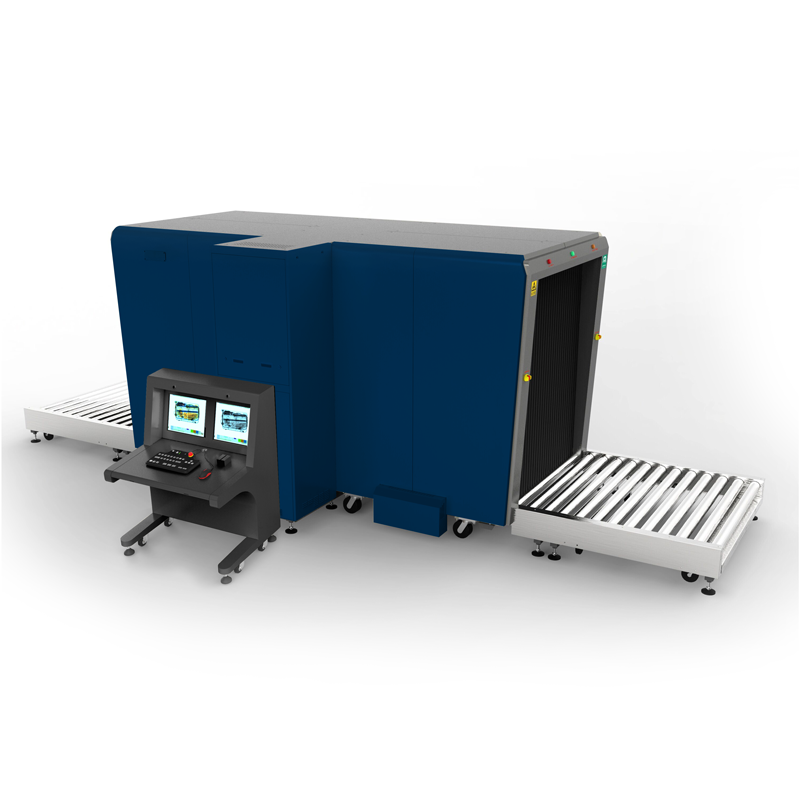

The 2MX-150180 is a heavy duty x-ray inspection system with a tunnel opening of 59″ x 71″. This scanner is designed for screening crates, cargo, and pallet-sized objects at all security sites, including airports and customs locations.

Product Highlights

- Radiation safe

- High resolution, high penetration and good image quality

- Multilingual operation

- Automatic built-in test and self diagnostics

- Super strong load-bearing capacity

- Threat alert and material classification

- Energy saving design

- One key turn off with patent

- Drugs and explosives detection

**Important Notes**

– This is not a medical device. It is intended for industrial or security purposes only.

AI Upgrade

This x-ray scanner can be upgraded with optional AI (artificial intelligence) technology to enhance image clarity and analysis with every scan. When enabled, AI not only delivers sharper, more detailed images but also automatically identifies and labels different objects. This feature makes it easier for operators to differentiate between harmless items and potential threats, reducing the chances of false alarms. Dangerous items such as weapons, contraband, and prohibited materials are automatically detected with greater accuracy and speed, ensuring nothing is missed. This optional AI feature boosts both the safety and efficiency of baggage inspections, making it an excellent choice for environments where security is a top priority.

Interested in This Product?

Let us know by completing the form, and we’ll contact you with the details you need to make the right choice.